Quality Manual for ISO/IEC 17020

Imagine your organization operating like a well-calibrated machine, where every process meets rigorous standards of quality and efficiency. ISO/IEC 17020 sets the stage for consistent service excellence within inspection bodies, but the cornerstone of its successful implementation lies in crafting a robust Quality Manual. This document not only serves as the blueprint for process adherence but also demonstrates your commitment to international best practices.

Navigating the complexities of ISO/IEC 17020 can seem daunting, with its intricate requirements and procedural specifics. Yet, understanding how to distill these into a comprehensive and clear Quality Manual is essential for any organization aspiring to either gain or maintain accreditation. The journey toward a gold standard in inspection quality management begins with a single step: a well-conceived Quality Manual.

In the following article, we will delve into the essentials of piecing together an effective Quality Manual tailored to ISO/IEC 17020. From grasping the fundamental purpose of the manual to documenting your procedures, and maintaining continuous improvement, this guide will travel with you through every pivotal phase of development. Let us embark on this pathway to quality excellence and accreditation success.

Introduction

A quality manual tailored to the needs and requirements of an inspection body forms the cornerstone of its commitment to integrity and excellence. In the world of conformance and meticulous scrutiny, ISO/IEC 17020:2012 stands as a critical standard, outlining the criteria for the operation of various types of bodies performing inspections. It encompasses aspects such as audit checklists, quality management, management reviews, and introduces a systematic framework to ensure that regulatory requirements are consistently met. The creation of a quality manual, therefore, is not just a matter of fulfilling an obligation but is pivotal in anchoring an organization’s methodical approach to quality and its ongoing management reviews.

The quality manual serves as a comprehensive document, essential for internal audits and reassurance to an accreditation body concerning an organization’s competence. As it details document methods, revisions, and control mechanisms, this manual reflects an inspection agency’s blueprint for maintaining high standards in quality documents and operational consistency. This article aims to guide you through the nuances of crafting a robust quality manual, with insights into leveraging document control software, engaging document control specialists, and implementing best practices for your document creation and management. It underscores the invaluable input from document control to avoid issues and ensure the creation of legal and regulatory compliant records.

Understanding the Quality Manual

A Quality Manual, as mandated by the ISO/IEC 17020 standard, serves as a cornerstone for inspection bodies aiming to ensure integrity and consistency in their operations. ISO/IEC 17020:2012 sets forth requirements for the competence of entities conducting inspections and for the impartiality and consistency of their inspection activities. The manual acts not only as a repository of processes and principles that guide the inspection body but also as a reflection of its commitment to quality management and regulatory compliance.

The quality manual outlines the organization’s structure and responsibilities, documenting the policies and procedures that shape its approach to quality management. The primary objectives of the manual are to establish a clear framework for processes, ensure consistent quality of services, and demonstrate the organization’s ability to meet customer and regulatory requirements.

The manual is instrumental for sustaining an operational consistency that lends itself to traceability and accountability within the organization. It is the nexus between the quality policy, procedures, and the records that are essential for the effective implementation of quality management systems.

The manual also intricately relates to various other documents such as audit checklists, management reviews, and quality documents created by document control specialists using document control software. These documents all play pivotal roles in maintaining a comprehensive understanding of the quality system, facilitating regular internal audits, management reviews, and continual improvement.

In conclusion, the Quality Manual is a core document that articulates an inspection body’s commitment to quality, describing the structure and operation of the management system, which underscores the foundation for achieving accreditation from the relevant accreditation body.

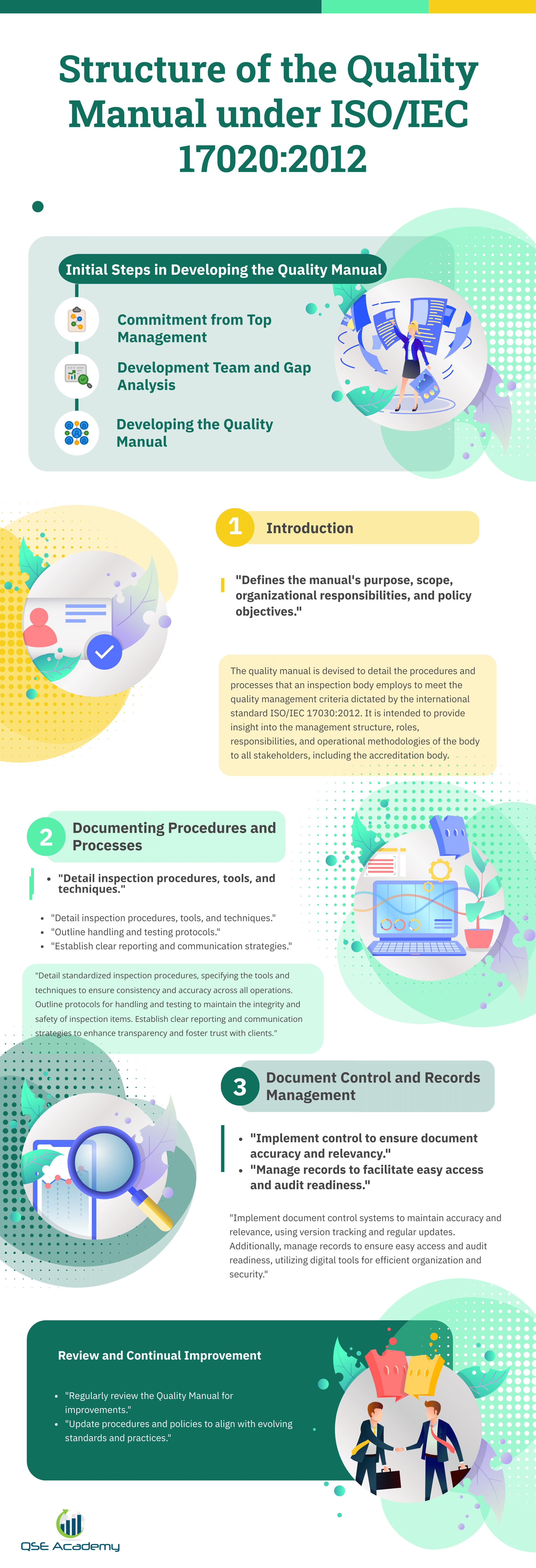

Initial Steps in Developing the Quality Manual

Developing a robust Quality Manual in line with ISO/IEC 17020:2012 is crucial for inspection bodies to demonstrate their ability to consistently operate competently and impartially. A comprehensive Quality Manual sets the stage for quality management and fulfills regulatory requirements.

Commitment from Top Management:

Successful implementation starts with unwavering commitment from the organization’s leadership. Top management’s support not only provides the necessary authority but also channels the organization’s vision into the development process. This leadership paves the way for the entire company to align with the quality objectives.

Development Team and Gap Analysis:

The formation of a dedicated development team is the next pivotal step. Comprising of document control specialists, quality documents managers, and stakeholders, this team brings diverse expertise to the table. They carry out a gap analysis to pinpoint the discrepancies between current practices and the standards required by ISO/IEC 17020.

Identifying Gaps and Action Plans:

Identifying these gaps highlights areas for improvement, leading to the formulation of a strategic action plan. This blueprint guides the necessary changes and facilitates the transition towards full compliance.

Understanding ISO/IEC 17020 Requirements:

A thorough comprehension of the requirements of ISO/IEC 17020 is indispensable. Key clauses of the standard inform the structure and content of the Quality Manual. Understanding these provisions ensures that the manual accurately reflects procedures, control of documents, management reviews, internal audits, and the roles of personnel involved in inspection activities.

Developing the Quality Manual:

Lastly, the development team embarks on creating the Quality Manual, ensuring it is a comprehensive document. They incorporate input from document control systems and address potential issues with document control, ensuring document accessibility through various platforms such as mobile phones and web-based interfaces, given that the use of Kindle devices might not be ideal in a professional setting.

In conclusion, the initial stages in developing a Quality Manual are critical, setting the foundation for a trustworthy inspection agency that meets the principles of ISO/IEC 17020 and satisfies the scrutiny of an accreditation body during audit checklists and management reviews.

Structure of the Quality Manual

The structure of the Quality Manual under ISO/IEC 17020:2012 is critical for the effective management and operation of inspection bodies. It serves as a comprehensive document that outlines the procedures and protocols necessary to ensure quality and regulatory compliance. The manual is organized into well-defined sections, each specified to encapsulate essential elements of the quality management system.

Section 3 of the Quality Manual typically covers the organizational structure and responsibilities. This vital component delineates the hierarchy of the inspection body and clarifies roles, thus ensuring accountability and clear communication channels. The chapter is organized to present information in an easily understandable format, often utilizing tables to depict the organizational structure and lists to itemize specific responsibilities.

Key elements in this section include:

- An Introduction to the organogram, detailing the relationship between different positions within the organization.

- A detailed list of responsibilities assigned to personnel, emphasizing the roles of management and key staff members.

- Procedures and processes that guide operations, including those specific to document control, ensuring consistent and up-to-date handling of all quality documents.

- Policies on document revisions, dictating how changes to documents are made and recorded, to maintain a high level of document integrity.

The Quality Manual must be both comprehensive and accessible, with document control software often employed to facilitate document creation, control, and revisions. With input from document control specialists, the manual remains a dynamically editable document, reflective of the organization’s current practices and compliant with ISO/IEC 17020:2012 requirements. This ensures that all involved parties, from management to on-the-ground inspectors, have access to the latest procedural information required for the proficient operation of inspection services.

Writing the Quality Manual

Quality management is the backbone of an effective inspection body, and ISO/IEC 17020:2012 outlines specific requirements for a comprehensive document, known as a quality manual, which is an essential tool to demonstrate competency and reliability. The Quality Manual acts not only as evidence of compliance with regulatory requirements but also as a guiding beacon for internal operations.

Purpose and Scope of the Quality Manual

The quality manual is devised to detail the procedures and processes that an inspection body employs to meet the quality management criteria dictated by the international standard ISO/IEC 17030:2012. It is intended to provide insight into the management structure, roles, responsibilities, and operational methodologies of the body to all stakeholders, including the accreditation body.

Organizational Structure and Responsibilities

An inspection body must neatly outline its organizational hierarchy, delineating the responsibilities at each level. Ensuring clarity in the management structure and the roles of personnel promotes accountability and facilitates internal audits and management reviews.

Quality Policy and Objectives

At the heart of the quality manual are the quality policy and objectives. Crafted with input from document control specialists, these should be explicit, aligned with the overarching mission of the body, and designed for regular examination and revision to drive continuous improvement.

When writing the quality manual, keep paragraphs concise and straightforward for accessibility. Incorporation of editable documents and usage of document control software can substantially reduce the cost and time of document preparation. Lists and tables should be utilized effectively to present audit checklists and document details like revisions and methods systematically.

In conclusion, drafting the quality manual is akin to mapping the DNA of an inspection body. It requires precision, foresight, and strategic input to ensure that the document not only meets the stipulated ISO/IEC 17020:2012 requirements but also serves as a living document that evolves with the body’s growth and changes in regulatory landscapes.

Documenting Procedures and Processes

In the domain of quality management, particularly for inspection bodies seeking to comply with ISO/IEC 17020, documenting procedures and processes is crucial. This standard provides a framework to ensure consistency, reliability, and efficiency in inspection activities.

Inspection Procedures

Inspection bodies must clearly outline standardized methods encompassing every step from planning to execution. This allows for uniform processes which can be accurately replicated, maintaining the quality of inspections.

Documentation of Inspection Techniques and Tools

Documenting the techniques and tools employed during inspections is integral for assuring service quality. This lies at the core of enabling a precise and methodical approach to inspections.

Handling of Inspection Items

Procedures for the meticulous receiving and management of inspection items are critical. It ensures the integrity and safety of items both during and after the inspection process.

Sampling, Testing, and Measurement Procedures

To reinforce the accuracy and dependability of tests and measurements, rigorous criteria and procedures must be administered. Detailed documentation serves as a reference point for both current operations and future reviews.

Reporting and Communication

The formation of comprehensive inspection reports and steadfast communication protocols is paramount. Timely communication with clients backed by transparent and documented findings embeds trust and credibility in the services provided.

Table: Key Areas of Documentation

| Documentation Area | Purpose |

| Inspection Procedures | To ensure standardized inspection practices |

| Techniques and Tools | To specify the detailed methodology and equipment utilized |

| Handling of Items | To maintain the condition and traceability of inspected items |

| Sampling and Testing | To validate the accuracy of inspection results |

| Reporting and Communication | To consolidate findings and maintain clarity with clients |

By adhering to these protocols, inspection bodies position themselves as diligent and dependable, adhering to the regulatory requirements and enhancing customer satisfaction.

Documenting inspection procedures and processes positively influences the efficacy and reliability of the inspection results which further bolsters an agency’s reputation. Internal audits and management reviews enhance this by ensuring ongoing compliance and continual improvement. Inspection bodies should leverage document control software and seek input from document control specialists to facilitate smooth document creation, revisions, and access, ensuring that every document, from audit checklists to quality documents, is comprehensive and up-to-date.

Document Control and Records Management

Document control and records management are pivotal in upholding the standards of a quality manual aligned with ISO/IEC 17020, which caters to inspection bodies. Effective document control ensures that only the current versions of required documents are in use, preventing outdated or erroneous information from disrupting operational integrity. To maintain this, document control procedures incorporate version control and a clear revision history, which records all changes made, who made them, and when.

Accessible yet secure documents are crucial. Access and distribution controls must be in place to warrant that sensitive information is only available to authorized personnel, protecting confidentiality and complying with data protection regulations.

Records management extends beyond mere document control. It involves the structured maintaining and storing of records, thus enabling easy retrieval. This functionality is not only a matter of regulatory requirement but also a practical necessity for management reviews and audits.

Speaking of internal audits, they are a regular feature in a comprehensive quality system. These audits are meticulously planned and executed, leading to a documentation process that captures findings and outlines necessary corrective actions. Audit checklists are often employed to streamline this process, ensuring all quality aspects are assessed uniformly.

Key Elements:

- Document Control

-

- Procedures: Defined methods for document creation, revisions, and approval.

-

- Version Control: Logged changes to prevent the use of obsolete documents.

-

- Access Control: Mechanisms to protect information and ensure it reaches only intended personnel.

- Records Management

-

- Storage: Secure and systematic arrangement for ease of access and preservation.

-

- Confidentiality: Measures to protect personal and sensitive data.

- Internal Audits

-

- Planning: A strategic approach to audit schedules and checklist formulation.

-

- Execution: Assessment of compliance and performance against the quality manual.

-

- Review: Documentation of audit results and follow-up on action items.

Careful documentation and proficient records management are essential for inspection bodies aspiring to meet the expectations of an accreditation body, as outlined in ISO/IEC 17020:2012. The ability to swiftly adapt and enhance quality documents is a testament to a robust and responsive quality management system.

Ensuring Continuous Improvement

Continuous improvement is a crucial aspect of maintaining a high standard within inspection bodies. To ensure ongoing development, a set of processes are implemented, centered around Key Performance Indicators (KPIs) and metrics. These are imperative for monitoring and evaluating performance effectively.

Inspection bodies are encouraged to regularly conduct performance reviews, which are documented meticulously as performance review records. This systematic approach helps in identifying areas that require enhancement. Feedback mechanisms play an essential role in the continuous improvement cycle. Client and stakeholder feedback is actively sought, gathered, and utilized to make informed decisions for future endeavors.

To document changes and foster progress, inspection agencies maintain comprehensive records of continuous improvement initiatives. These records are not only instrumental in tracking the outcomes but also serve as evidence of the organization’s commitment to quality and excellence.

Additionally, when improvements are implemented, documenting changes becomes essential. It not feels the need to chart the journey of advancement but also ensures that all improvements are traceable and can be reviewed for effectiveness. Tracking progress is facilitated through measurable outcomes that show the journey from the current state to the achieved improvements.

The dedication to continuous improvement is also apparent in how feedback is leveraged to refine procedures and practices, thus aligning with regulatory requirements and the expectations of the accreditation body.

| Performance Metrics | Description |

| KPIs | Quantitative measures of performance. |

| Feedback Utilization | Incorporating suggestions for improvement. |

| Improvement Tracking | Documenting progress and outcomes. |

In a culture driven by constant evolution, inspection bodies make use of these strategies to not only meet but exceed the benchmarks set by both the industry and ISO/IEC 17020:2012 standards.

Implementing and Maintaining the Quality Manual

Implementing and maintaining a quality manual as per ISO/IEC 17020:2012 is crucial for inspection bodies wishing to demonstrate their commitment to delivering reliable and consistent services. The quality manual serves as a cornerstone document that outlines the processes and procedures needed to meet the standard’s stringent guidelines, as well as regulatory requirements.

To ensure that the manual remains relevant and effective, regular training programs are essential. These programs are designed to educate personnel on the importance of the quality manual, ensuring that every team member understands their responsibilities and how to adhere to the documented procedures.

Moreover, the quality manual is not a static document; it requires ongoing attention and maintenance. This encompasses periodic reviews and revisions to keep the manual up-to-date with any changes in procedures, policies, or ISO/IEC 17020 updates. It is a living document that evolves along with the organization.

Maintaining compliance with ISO/IEC 17020 necessitates regular internal audits. These audits serve as an internal checkpoint, helping to identify areas of improvement and ensuring that processes are being followed as documented. Management reviews also play a critical role, providing an opportunity for senior leadership to assess the effectiveness of the quality management system.

In summary, regular updates, employee training, diligent internal audits, and management reviews are key components for implementing and maintaining a quality manual that meets the quality management standards required by ISO/IEC 17020:2012. This ongoing process not only supports continuous improvement within the organization but also fosters trust and confidence among clientele and the accreditation body.

| Component | Implementation Strategy |

| Training | – Tailored programs for personnel |

| – Fostering understanding and adherence | |

| Maintenance | – Periodic reviews and updates |

| Compliance | – Regular internal audits and management reviews |

| Documentation | – Updating procedures as needed |

| Reviews | – Ensuring the effectiveness of the quality system |

Conclusion

In conclusion, the essence of a high-quality manual, particularly in the context of ISO/IEC 17020:2012, cannot be overstated. It serves as a cornerstone for inspection bodies, ensuring they operate with a consistent framework that not only meets but goes above and beyond regulatory requirements. A well-crafted quality manual encompasses thorough audit checklists, clear strategies for quality management, and detailed management reviews, all of which underline the manual’s criticality.

Key elements such as document control software, the involvement of document control specialists, and the utilization of editable documents streamline the creation and revisions process, ensuring document methods and details are up-to-date and accessible across various platforms – whether it’s on a mobile phone or through Kindle for Web. Recognizing the cost and effort in document preparation, inspection agencies are encouraged to see it as an investment in sustainability and excellence.

Through continuous updates and input from management and staff, the quality manual remains a living document, integral to internal audits and inspection efficacy. There’s a clear call to action for all types of bodies performing inspections to establish, refine, and maintain a comprehensive quality manual. It’s not merely about achieving accreditation but fostering a culture of persistent improvement and upholding the highest standards of service.

Looking for More Resources on ISO 17020?

If you found this article helpful, explore our premium resources designed to help you achieve ISO 17020 certification efficiently:

- 📦 Complete Documentation Package for ISO/IEC 17020 2012: Get all the essential templates and documents you need for fast, easy implementation.

- 🎓 Online Course on ISO/IEC 17020 2012 : Enroll in our comprehensive training to master the key concepts and practical steps toward certification.

- 📋 ISO/IEC 17020 2012 Checklist: Download our detailed checklist to ensure you’ve covered every step of the process.

These resources are tailored to meet your needs and ensure a smooth certification journey. Explore them today and get one step closer to success!