Audit Process for ISO/IEC 17020 Compliance

Navigating the labyrinth of compliance can be as daunting as threading a needle in a hurricane, particularly when it involves the complexities of ISO/IEC 17020. ISO/IEC 17020 sets the global benchmark for inspection bodies, dictating rigorous requirements to guarantee precision, impartiality, and operational integrity. This standard’s documentation requirements are a foundational component, integral to proving adherence and maintaining accreditation.

In a landscape where credibility is currency, ISO/IEC 17020 serves as a hallmark of trust for inspection agencies. These agencies are pillars in various sectors, from engineering to environmental health, and their compliance with ISO/IEC 17020 assures the validity of their inspections. Understanding the essentials of ISO/IEC 17020’s documentation not only fosters compliance but also reinforces an organization’s commitment to excellence.

In the following sections, we will dissect ISO/IEC 17020’s documentation requirements, exploring the keys to creating a robust framework for conformity. From the specifics of process documentation to effective record keeping, each part will provide insight into the meticulous world of ISO/IEC 17020 compliance. Join us as we embark on a journey through the critical aspects of documentation that underpin the credibility and operational soundness of inspection bodies.

Introduction

ISO/IEC 17020, titled “Conformity assessment — Requirements for the operation of various types of bodies performing inspection,” is a globally recognized standard that delineates the quality and competence criteria inspection bodies must meet to be considered reliable and credible. Establishing trust in the inspection process is critical, and ISO/IEC 17020 sets forth a framework for inspection bodies to ensure they operate impartially and with the requisite technical competence. Adherence to this standard is particularly vital because it not only enhances confidence in the inspections carried out by these bodies but also assures customers and regulatory authorities of the quality and legality of the results.

This article aims to serve as a concise and clear guide for those involved in complying with ISO/IEC 17020, especially concerning the essential documentation necessary for meeting the standard’s provisions. Proper documentation is the cornerstone of compliance, facilitating the standardization of processes and providing a clear audit trail. Our guide will elucidate the types of documents required and their functions, helping ensure your inspection body aligns with ISO/IEC 17020’s rigorous requirements. Through structured information and easy-to-understand formatting, including tables and lists, this guide aims to simplify the road to compliance for inspection entities.

Understanding ISO/IEC 17020

ISO/IEC 17020 is an internationally recognized standard that delineates requirements for the competence of bodies performing inspection activities. Its scope spans various types of inspection bodies, dictating how they should operate to ensure trust in their inspection services.

At the core of ISO/IEC 17020 lie key objectives that aim to instill confidence in both clients and regulatory entities. These objectives focus on the impartiality, consistency, and reliability of inspection practices. Inspectors must display competence, and their activities should be conducted methodically, irrespective of the item being inspected or the inspection process.

Documentation under ISO/IEC 17020 is critical. It is the cornerstone that supports the standard’s objectives by ensuring that inspection processes are repeatable and based on documented evidence. It aids in maintaining transparency, thereby enhancing accountability, and facilitates the replication of the inspection processes if needed.

There are different types of inspection bodies: Type A, Type B, and Type C. They have distinct operational characteristics:

- Type A: Fully independent bodies that have no involvement with the design, manufacture, supply, installation, use, or maintenance of the items they inspect.

- Type B: Separate and identifiable parts of organizations that provide products or services not covered by the inspection body but may engage in activities that could compromise impartiality.

- Type C: Inspection bodies that are part of organizations that design, manufacture, supply, install, use, or maintain the items they inspect, which could impact their impartiality without proper safeguards.

Understanding the definitions and differences between these types ensures clarity in their application and adherence to the principles outlined in ISO/IEC 17020.

Key Documentation Requirements

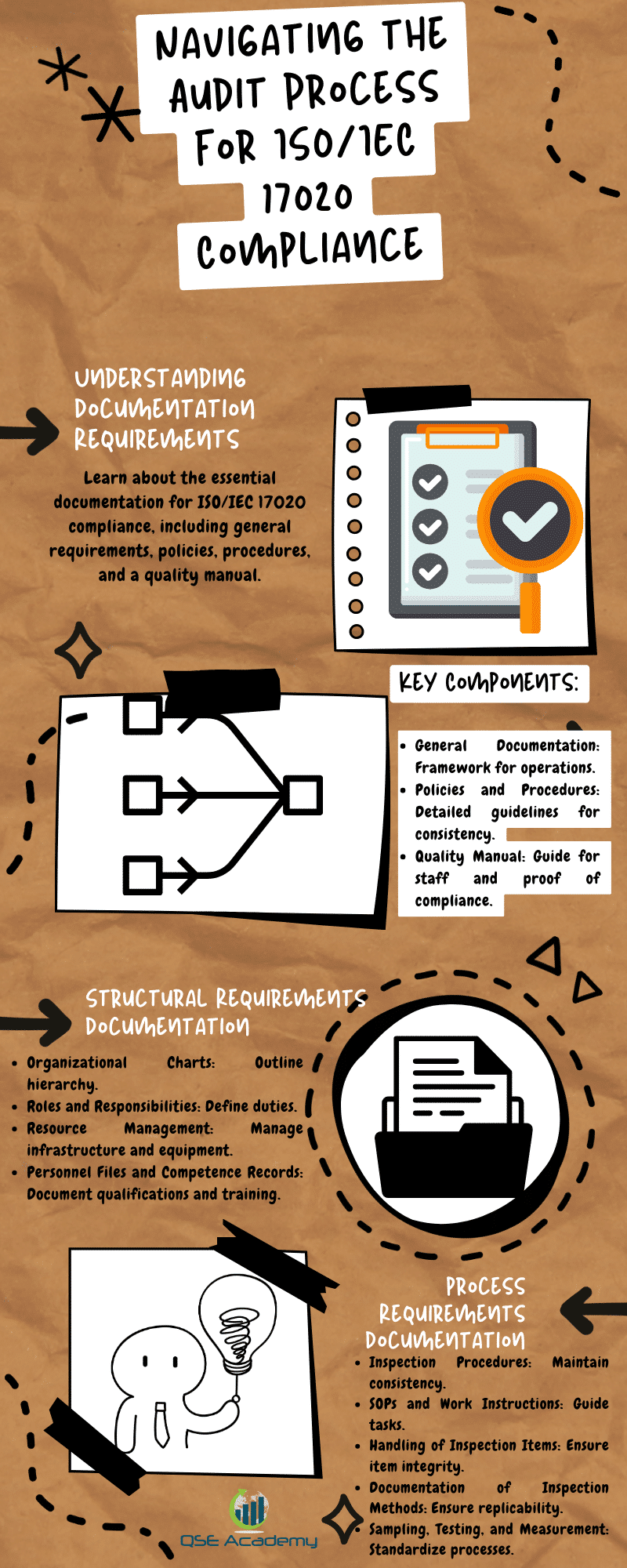

ISO/IEC 17020:2012 outlines critical documentation requirements for entities seeking compliance or accreditation as inspection bodies. Essential documents encompass general requirements, policies and procedures, and a quality manual. These documents create a framework ensuring services meet and maintain high standards.

- General Documentation: It marks the foundation for consistent operations within an inspection body.

- Policies and Procedures: Clearly articulated policies and procedures are vital, detailing how to conduct inspections to recognized standards, ensuring consistency, and controlling records.

- Quality Manual: This pivotal document outlines the management system, objectives, and commitments to quality. It serves as a guide for staff and demonstrates compliance to accrediting bodies.

Legal and contractual records are likewise significant:

- Legal Documents: Compliance with legal and regulatory frameworks is imperative, and proper documentation should reflect this adherence.

- Client Contracts and Agreements: These formalize expectations and safeguard both the inspection body and the client, defining scope, responsibilities, and confidentiality.

Lastly, impartiality and independence are central to an inspection body’s integrity:

- Impartiality Policies: A set of policies is needed to reinforce the unbiased nature of the inspection processes.

- Conflict of Interest Declarations: Members disclose potential conflicts, ensuring transparency and trust in the body’s independence.

Table: ISO/IEC 17020 Key Documentation Components

| Component | Description |

| General Documentation | Base framework for operations |

| Policies and Procedures | Descriptions of processes for quality and consistency |

| Quality Manual | Comprehensive guide on quality management systems |

| Legal Documents | Proof of legal compliance |

| Client Contracts | Terms and relationships with clients |

| Impartiality Policies | Guarding against bias in operations |

| Conflict of Interest Declarations | Transparency in potential conflicts |

These documents are non-negotiable for ISO/IEC 17020-compliant inspection bodies, ensuring that they hold themselves to the highest quality and ethical standards.

Structural Requirements Documentation

ISO/IEC 17020:2012 is an important international standard that specifies requirements for the competence of entities performing inspection and for the impartiality and consistency of their inspection activities. One of the crucial aspects of complying with ISO/IEC 17020 is maintaining comprehensive structural requirements documentation. Below is a concise overview of the essential components for Section 3: Structural Requirements Documentation, structured to provide clarity and ease of understanding.

Organizational Structure: A well-defined organizational structure is fundamental for any ISO/IEC 17020 compliant entity. Documentation should clearly outline the hierarchy and framework within which the inspection body operates.

Organizational Charts: Visual representations, such as organizational charts, are vital as they provide a snapshot of the key personnel and their hierarchical relationships within the organization.

Roles and Responsibilities: Detailed documentation of roles and responsibilities ensures that each team member is aware of their specific functions and duties. This clarity is pivotal for maintaining the quality and integrity of inspection processes.

Resource Management: In terms of infrastructure and equipment, it is crucial to document how resources are managed, allocated, and maintained to support the operational effectiveness of the inspection body.

Personnel Files and Competence Records: It is imperative for the internal records to diligently document the qualifications, experience, and ongoing training of all personnel to showcase their competence and capability to fulfill their assigned roles.

In light of these facts, organizations should methodically document the aforementioned structural requirements to ensure that inspections are conducted by competent staff, within an organization that is structured to support impartiality, confidentiality, and the consistent application of inspection activities.

Here’s a tabular summary of the documentation required for Section 3:

| Document Type | Purpose |

| Organizational Chart | To describe organizational hierarchy and structure |

| Roles and Responsibilities Documents | To outline the duties and expectations for each role |

| Resource Management Records | To detail how resources are handled and maintained |

| Personnel Files and Competence Records | To prove the qualifications and expertise of staff |

Maintaining these records with diligence and regular updates is a foundational requirement for inspection bodies committed to excellence and compliance with ISO/IEC 17020 standards.

Process Requirements Documentation

ISO/IEC 17020 is a standard governing the requirements for the operation of various types of bodies performing inspection. Adherence to this standard ensures that inspections are conducted with impartiality, consistency, and reliability. Under Section 4, the Process Requirements Documentation is crucial for fulfilling the standard’s stipulations.

Inspection Procedures: Organizations must document detailed procedures for their inspection activities. This aids in maintaining consistency and ensures that inspections are performed according to the prescribed guidelines and regulations.

Standard Operating Procedures (SOPs) and Work Instructions: SOPs outline the methodical steps for inspection processes, while work instructions provide specific instructions for carrying out tasks. These documents assist in the training of personnel and serve as a reference during inspection activities.

Handling of Inspection Items: Procedures for receiving and handling items are put in place to prevent contamination, damage, or loss. Proper documentation ensures the integrity of the items from receipt through to the inspection process.

Documentation of Inspection Methods: It is imperative that methods used during inspections are well-documented to guarantee that they meet the necessary criteria and can be replicated or audited if necessary.

Sampling, Testing, and Measurement: Sampling plans and criteria need to be established and documented, ensuring that samples are representative and that testing and measurement procedures are up to standard.

Calibration and Maintenance Records: Maintaining accurate records of equipment calibration and maintenance is essential. This ensures that inspections are accurate and that equipment is functioning properly.

In summary, organizations conforming to ISO/IEC 17020 must maintain comprehensive documentation as per Section 4 to uphold the trustworthiness and legality of their inspection processes. These documents provide a foundation for performing consistent, correct, and repeatable inspections.

Management System Documentation

Implementing an ISO/IEC 17020-compliant Management System necessitates rigorous documentation to establish a clear framework of operations for inspection bodies. This encompasses a seamless integration of the organization’s Quality Manual and underlying policy documents which anchor the system.

The Quality Manual stands at the heart of the documentation process, detailing the structure and content of the management system while aligning it with the organization’s goals. It serves as the cornerstone, outlining responsibilities, protocols, and the mechanism for maintaining quality standards.

Policy documents complement the manual, providing an in-depth look at specific policies the organization adheres to. These govern the operational ethos and the benchmarks for performance and compliance.

To visualize processes, process maps and flowcharts are indispensable. They offer a bird’s eye view of procedural flow, clarifying steps and identifying potential bottlenecks or inconsistencies.

Regular internal audits and periodic management reviews enforce accountability and continuous improvement. These activities are meticulously recorded through:

- Audit schedules and checklists: Tools that guide auditors in a comprehensive evaluation.

- Management review minutes and action plans: Documentation of discussions and strategic decisions ensuring timely execution of plans.

To keep a tab on discrepancies and promote a culture of improvement, non-conformity reports are pivotal. They pinpoint areas where standards fall short. Subsequently, records of corrective and preventive actions serve as evidence of proactive remediation and continuous enhancement of the Quality Management System. These records form a critical part of the feedback loop, ensuring the resilience and integrity of the inspection services provided.

| Documentation Type | Purpose |

| Quality Manual and Policy Documents | Define the management system structure and organizational policies |

| Process Maps and Flowcharts | Visualize and communicate process flows |

| Audit Schedules and Checklists | Standardize and guide audit activities |

| Management Review Minutes and Action Plans | Record deliberations and planned improvements |

| Corrective and Preventive Actions | Document measures taken to rectify and prevent issues |

| Non-Conformity Reports | Identify and track non-conformances |

Maintaining these documents in an organized, accessible manner is crucial for the successful implementation and management of the Quality Management System as per ISO/IEC 17020 standards.

Record Keeping and Document Control

Record keeping and document control are vital components of ISO/IEC 17020 compliance, according to which organizations must establish stringent procedures. Documents must be regularly reviewed, with revisions meticulously recorded to maintain version control. Control procedures ensure only valid documents are accessible to authorized personnel, minimizing the risk of utilizing outdated or incorrect information.

Records should be easily retrieable, and organizations must define the retention periods, depending on the record type, to comply with legal and operational requirements. A secure storage system protects sensitive information from unauthorized access and environmental hazards, ensuring the integrity and confidentiality of data.

To prevent data loss and corruption, stringent data protection measures such as regular backups and robust recovery plans should be in place. These strategies are essential to safeguard the organization’s critical information assets and ensure continuity in case of unexpected events.

Key aspects of effective record keeping and document control include:

- Controlled access to prevent unauthorized distribution.

- Defined retention periods for various records.

- Secure and organized archiving systems.

- Regular validation of data integrity.

- Backup systems and disaster recovery protocols.

By adhering to these guidelines, organizations will uphold the high standards set by ISO/IEC 17020 for documentation and record management.

Training and Competence Documentation

ISO/IEC 17020 is an internationally recognized standard for the competence of inspection bodies. Section 7 of this standard is specifically dedicated to Training and Competence Documentation, which is central to ensuring the quality and integrity of inspections.

To comply with Section 7, inspection bodies must maintain robust training programs. These include documented training plans and schedules that outline the specific learning objectives and timelines for all personnel. Documentation should be clear, updated regularly, and accessible for review when necessary.

Training records are crucial under this section, as they provide evidence of each individual’s attendance and the assessment of their training sessions. This ensures that personnel have not only participated but also understood the training and are thereby qualified to perform their assigned duties.

Furthermore, competence assessment is mandated by ISO/IEC 17020. The methods for evaluating competence must be established, standardized, and documented. It may involve practical examinations, observations, or other relevant evaluations to confirm that an inspector is capable of performing their role to the standard required.

Lastly, records of evaluations and certifications must be kept. These records serve as a formal certification of competence and must be rigorously managed. They prove that personnel have been assessed and have met the defined criteria for their specific roles within the inspection process.

In summary, documentation under Section 7 of ISO/IEC 17020 is crucial for demonstrating that inspection bodies have a structured process to maintain and improve the competence of their staff. Inspection bodies should ensure that this documentation is regularly reviewed, updated, and available for accreditation purposes.

Maintaining Compliance and Continuous Improvement

ISO/IEC 17020 Documentation plays a vital role in ensuring that inspection bodies maintain compliance and strive for continuous improvement. Central to this endeavor are systematic monitoring and measuring of performance. Utilizing Key Performance Indicators (KPIs) enables organizations to quantify their effectiveness and efficiency. Such metrics may consider aspects like inspection accuracy, timeliness, and customer satisfaction.

Performance reviews and assessments must be conducted regularly, offering a reflective overview of operational strengths and areas needing attention. These evaluations are not only aimed at ensuring adherence to standards but also at fostering an environment of ongoing enhancement.

Feedback mechanisms are integral to this process. The insights gleaned from clients and stakeholders can guide an organization to fine-tune its services. Maintaining detailed records of feedback, along with subsequent actions taken, is imperative. This not only demonstrates responsiveness but also aids in tracking the impact of changes implemented.

Continuous improvement is an expectation set by ISO/IEC 17020, and inspection bodies should diligently record all improvement initiatives. By monitoring the progress and outcomes of these measures, an organization can substantiate its commitment to elevating its service quality and compliance status over time.

Utilizing a table can help organize KPIs and performance reviews efficiently:

| KPI Category | Objective | Measurement | Frequency of Review |

| Accuracy | Minimize incorrect inspection findings | Number of findings overturned upon review | Quarterly |

| Timeliness | Conduct inspections within agreed timeframes | Average time from request to inspection completion | Monthly |

| Customer Satisfaction | Achieve high client approval ratings | Survey scores and feedback | Biannually |

Incorporating a list can illustrate steps for handling feedback:

- Collect Feedback: Gather input from various sources.

- Record and Analyze: Detail feedback and examine it for actionable insights.

- Act: Implement necessary changes based on feedback.

- Follow-up: Review and assess the effectiveness of the responses taken.

Through a structured approach to monitoring, review, feedback incorporation, and documentation, ISO/IEC 17020 compliant inspection bodies can sustain compliance while driving continual advances in their operations.

Continuous Improvement Documentation

ISO/IEC 17020 provides guidelines to ensure that inspection bodies operate in a competent, consistent, and impartial manner. Toward continuous improvement, this standard requires documentation that supports the enhancement of the inspection process and overall quality management system. Effective documentation practices include establishing clear procedures for identifying and managing non-conformities, corrective actions, and monitoring the implementation of improvements.

Various industries provide case studies demonstrating the benefits of meticulous ISO/IEC 17020 documentation. For example, in the manufacturing sector, a company might document changes in inspection procedures that led to a reduction in defective products. In the environmental sector, an inspection body might maintain records of improved data collection methods for pollution assessment, contributing to more accurate and reliable reporting.

Lessons learned highlight the importance of recording audit trails and feedback, which enable inspection bodies to trace issues back to their sources and prevent future occurrences. Challenges often arise from inadequate documentation control; however, implementing digital systems can streamline documentation processes and increase accessibility.

Effective documentation has led to measurable benefits, such as increased confidence in inspection results, enhanced reputation among stakeholders, and a solid foundation for making informed decisions. To illustrate, the following table summarizes key documentation practices associated with continuous improvement in ISO/IEC 17020 compliant inspection bodies:

| Documentation Practice | Description | Result |

| Non-Conformity Logs | Detailed records of non-conformance instances | Identification of patterns and areas for improvement |

| Corrective Action Plans | Steps for addressing identified issues | Systematic resolution and prevention of issues |

| Improvement Monitoring | Tracking the efficacy of actions taken | Verification of continuous improvement efforts |

Conclusion

In conclusion, the essence of meticulous and accurate ISO/IEC 17020 documentation cannot be overstated for inspection bodies. Adhering strictly to this set of international standards not only promotes a culture of excellence and reliability but also fortifies the trust between clients and stakeholders. The precise maintenance of records, procedures, and policies ensures that inspection processes are transparent, consistent, and repeatable, thereby enabling accountability and a framework for addressing any discrepancies.

Embracing the benchmarks set by ISO/IEC 17020 and staying compliant with its requirements offers numerous benefits. It mitigates risks, fosters continual improvement, and can often be a gateway to unlocking new market opportunities. Moreover, compliance is a testament to the professionalism and commitment of the inspection body to quality and customer satisfaction.

As an ongoing process, ISO/IEC 17020 demands regular reviews and updates of documentation to keep pace with changes in technology, industry practices, and regulatory landscapes. Therefore, inspection bodies should not only establish but relentlessly pursue robust documentation practices. This dedication will ensure that they not only meet but exceed the standards, thus enhancing their credibility and competitive edge in a dynamic global market.

Looking for More Resources on ISO 17020?

If you found this article helpful, explore our premium resources designed to help you achieve ISO 17020 certification efficiently:

- 📦 Complete Documentation Package for ISO/IEC 17020 2012: Get all the essential templates and documents you need for fast, easy implementation.

- 🎓 Online Course on ISO/IEC 17020 2012 : Enroll in our comprehensive training to master the key concepts and practical steps toward certification.

- 📋 ISO/IEC 17020 2012 Checklist: Download our detailed checklist to ensure you’ve covered every step of the process.

These resources are tailored to meet your needs and ensure a smooth certification journey. Explore them today and get one step closer to success!